What is Industrial Revolution 4.0 and Its Importance Explained. Industry 4.0 or Fourth Industrial Revolution is the ongoing automation of traditional manufacturing and industrial practices, using modern smart technology. In this Article Learn about Fourth Industrial Revolution In Detail. After reading this Article you will be able to Answer about the Evolution of Industrial Revolution, What is Fourth Industrial Revolution or Industry 4.0, What Drive the Change to Industry 4.0, Impact of Industry 4.0, Industry 4.0 Post COVID – 19, History of Indian Industrial Revolution and India and Industry 4.0

Why In News?

Prime Minister Narendra Modi on 8th July (Thursday) interacted with the Directors of centrally-funded technical institutions emphasizing that higher educational institutions need to prepare the youth for continuous disruptions and changes, keeping in mind the fourth industrial revolution.

What is the Fourth Industrial Revolution?

The Fourth Industrial Revolution (4IR or Industry 4.0) is the ongoing automation of traditional manufacturing and industrial practices, using modern smart technology.

Large-scale machine-to-machine communication (M2M) and the internet of things (IoT) are integrated for increased automation, improved communication and self-monitoring, and production of smart machines that can analyze and diagnose issues without the need for human intervention

The phrase Fourth Industrial Revolution was first introduced by a team of scientists developing a high-tech strategy for the German government

Fourth Industrial Revolution will be marked by breakthroughs in emerging technologies in fields such as robotics, artificial intelligence, nanotechnology, quantum computing, biotechnology, the internet of things, the industrial internet of things, decentralized consensus, fifth-generation wireless technologies, 3D printing, and fully autonomous vehicles.

The Evolution of the Industrial Revolution

The Industrial Revolution, which took place from the 18th to 19th centuries, was a period during which predominantly agrarian, rural societies in Europe and America became industrial and urban.

Prior to the Industrial Revolution, which began in Britain in the late 1700s, manufacturing was often done in people’s homes, using hand tools or basic machines. However, these cottage industries were enormously labour intensive, with the merchants supplying the raw materials and collecting the finished goods later. The whole process was largely inefficient. The supply was erratic as the self- employed workers had to tend other works.

|

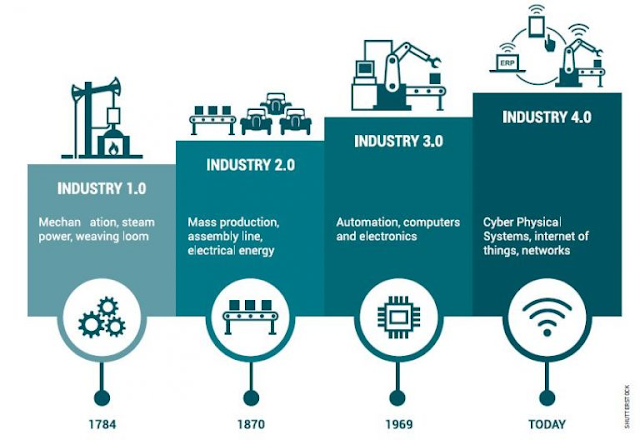

Fig. 1.1 The Evolution of the Industrial Revolution |

The First Industrial Revolution was marked by a transition from hand production methods to machines through the use of steam power and water power. The first Industrial Revolution started in 1784 and was famous for producing the steam engine.

The Second Industrial Revolution, also known as the Technological Revolution, is the period between 1871 and 1914 that resulted from installations of extensive railroad and telegraph networks, which allowed for faster transfer of people and ideas, as well as electricity. Increasing electrification allowed for factories to develop the modern production line

The third revolution started in 1969 and is officially known as the digital revolution, where the use of PLC (Programmable Logic Controller) and IT was rolled out to speed up production and improve the quality of the finished product.

It is seen that each revolution took about a hundred years to establish and then give way to the next revolution.

Now a Fourth Industrial Revolution is building on the third revolution, that is, the digital revolution that has been occurring since the middle of the last century. It is characterized by a fusion of technologies that is blurring the lines between the physical, digital, and biological spheres.

What Drive the Change to Industry 4.0:?

- Technological breakthroughs: New technological innovations such as Big Data, 3-D printing, artificial intelligence and robotics is bringing transformative impact on the nature work.

- Demographic Changes: the world’s population is ageing, putting pressure on business, social institutions and economies. The shortage of a human workforce in a number of rapidly-ageing economies has necessitated automation.

- Rapid urbanization: The UN projects that by 2050, the world’s urban population will increase by some 72%. Rapidly growing cities have become drivers of a new industrial revolution.

- Shifts in global economic power: Power shifting between developed and developing countries with a large working-age population will attract investments and become a driving force for the future of work.

- Resource scarcity and climate change: According to the report Global Trends 2030, demand for energy and water is forecast to increase by 50% and 40% respectively by 2030. Jobs in alternative energy, new engineering processes, product design and waste management and re-use will be created.

Impact of Industry 4.0

- Near real time communication between systems.

- Cost effective decentralized decision – These digital technologies can create virtual versions of real-world installations, processes and applications. This can then be robustly tested to make cost effective decentralized decisions.

- Disruptive Change in the process - Computers are connected and communicate with one another to ultimately make decisions without human involvement.

- Creation of Smart Factory – Due to the support of smart machines that keep getting smarter as they get access to more data, our factories will become more efficient and productive and less wasteful.

- Creation and Sharing of Vast amount of data – Which in turn will help in future planning and decision making.

Industry 4.0 Post COVID – 19

The business drivers of Industry 4.0 pre-crisis were focused on competitive advantage, cost reduction, productivity, sustainability and innovation. The goal was to make smooth businesses to run better.

However, post crisis scenario would change dramatically. The focus for many manufacturers now is survival first and foremost and beyond that, damage limitation.

Once survival is ensured, manufacturers would want to take their businesses to a stable region which can be called Business as usual in the new post crisis paradigm.

To reach there as soon as possible at the lowest cost, they need real time visibility across the business. For example- What is the demand for products and where can we manufacture them?

Another key learning from the crisis will be driven by manufacturers’ reliance on human capital and the impacts of social distancing.

In this context, it can be said that Industry 4.0 is not only as applicable as it was before but it is actually far more relevant.

COVID-19 has provided another strong incentive to move towards a smart factory, complete with smart manufacturing smart printing processes.

History of Indian Industrial Revolution

India was famous for her handicrafts from the pre-British times. In Mughal periods such as the variety of handicrafts that it became famous in the global market.

However, the Industrial Revolution came late to India. This was mainly because of India’s complicated political and economic relations with Britain. The use of steam power in British mills reduced the cost of British cotton by 85%, making its textile goods internationally competitive for the first time.

Britain quickly became a leading world exporter of textiles, displacing India in the process. In addition, in order to protect its new textile industry, Great Britain began to restrict its textile imports from India and other countries, by establishing tariffs and other protective policies.

Great Britain began to export its own textiles to India. This led to India’s de-industrialization. British lawmakers pushed India towards becoming more agrarian than an industrialized nation.

New colonial laws forced Indian farmers to devote fields to cotton crops, instead of food and this led to widespread famine and poverty in India.

The industrial revolution was in fact the worst period for the Indian economy. The industrial revolution reversed India’s economic relationship with Great Britain, to make it predominantly a supplier of raw material for Great Britain and an importer of British textiles instead of a producer of textile goods.

Unfortunately, India was only able to capture a part of the third industrial revolution and not the full measure of it. Our production processes had not really become smart and there were still a lot of legacy issues that crippled us.

During the 1st stage of the industrial revolution (which was around the 1760’s or so), India missed the bus. At this stage the political system in India was in a stage of transition. Europe occupied a position of ascendancy. In the second phase of the industrial revolution, what happened was that we (India) were still under the colonial masters and we were not really able to capture the benefits of the second industrial revolution as well.

By the time the third phase of the industrial revolution had come, we had become an independent country, and we did capture some of the value-add, but it is only now that because of the advantage that is created by the young population; and that our industrial processes have become smarter; the fact that India is now an IT powerhouse that we can now hope and aspire to capture the full benefit of the industrial revolution.

India and Industry 4.0

Innovation Is fundamentally undergoing a radical change. The scale, scope, and complexity are things we have certainly never experienced. It is exposing us to exponential technologies.

India has also taken early steps to take benefits from Fourth Industrial Revolution and place itself in the list of leading countries who have taken great leap in transforming itself as per the need of Industry 4.0

Centre for the Fourth Industrial Revolution was inaugurated by PM Modi in 2018, which is an initiative of the World Economic Forum.

The National Institute for Transforming India (NITI) Aayog is the designated nodal agency to interact with the World Economic Forum for elaborating the new policy frameworks for emerging technologies

India became the fourth country in the world after USA, China and Japan where the World Economic Forum (WEF) opened its Centre for the Fourth Industrial Revolution India.

Government is working to improve people’s lives and prepare the youth for changing technologies through schemes like Skill India, Startup India, Atal Innovation Mission (AIM), Digital India, and others.

Samarth Udyog Bharat 4.0 (Smart Advanced Manufacturing and Rapid Transformation Hubs) under the Department of Heavy Industries (Ministry of Heavy Industries & Public Enterprises) is the India’s initiative to push for Industry 4.0 implementation with an aim to propagate technological solutions to Indian manufacturing units by 2025 through steps like awareness programme, training, demo centers etc

India’s National Manufacturing Policy (NMP) has been promulgated which aims at enhancing the share of manufacturing in GDP to 25% and Industry 4.0 is the only way ahead to achieve this task.